No.898 West Huanghe Road, Changzhou, Jiangsu, P.R.of China +86-182 06118609 [email protected]

The grader is a kind of high speed, high precision and multi-purpose earthmoving machinery. It can complete the road important content field, farmland and other large areas of ground leveling and trenching, scraping, soil, snow, loose, compaction, cl...

Share

The grader is a kind of high speed, high precision and multi-purpose earthmoving machinery. It can complete the road important content field, farmland and other large areas of ground leveling and trenching, scraping, soil, snow, loose, compaction, cloth, mixing, auxiliary installation and clearing work. It is an important equipment in mine construction, road construction, water conservancy construction and farmland improvement.

| Products | Model | Operating Weight | Rated Power | Blade Width | Introduce |

| Motor Grader | 713H | 12000kg | 97kW | 3658mm | Our 713H motor grader adopts power shift transmission featuring sing-handle manipulation and electro-hydraulic control. With 6 forward and 3 reverse gears shifting, the vehicle is easy and convenient to operate. It also utilizes a highly efficient hydraulic system with hydraulic lock, enabling normal operation of every unit. Moreover, the fully hydraulic brake system provides high working safety and reliability for the equipment. |

| 715H | 12000kg | 110kW | 3658mm | 715H motor grader adopts power shift transmission featuring sing-handle manipulation and electro-hydraulic control. With 6 forward and 3 reverse gears shifting, the vehicle is easy and convenient to operate. It also utilizes a highly efficient hydraulic system with hydraulic lock, enabling normal operation of every unit. Moreover, the fully hydraulic brake system provides high working safety and reliability for the equipment. | |

| 717H | 14500kg | 132kW | 3658mm | Sing-handle electro-hydraulic controlled power-shift T/M, 6 forward&3 reverse shifts makes operation easy and convenient;Hydraulic lock, auto lock/unlock NO-SPIN differential ensures stability;Powerful traction deal axle load allocation provides excellent stability while cutting hard surface | |

| 719H | 15600kg | 142kW | 4268mm | This 719H Motor Grader is equipped with reliable ShangChai SC11CB195G2B1 engine or genuine Cummins engine;Sing-handle electro-hydraulic controlled power-shift T/M, 6 forward & 3 reverse shifts makes operation easy and convenient;Hydraulic lock, auto lock/unlock NO-SPIN differential ensures stability and powerful traction;Ideal axel load allocation provides excellent stability while cutting hard surface. | |

| 722H | 16100/15800kg | 162/160kW | 4320mm | Our 722H motor grader adopts ShangChai engine ,The adopted hydraulic system can achieve efficient control over every working part.When combined with box-typed frame, the transmission system allows the vehicle to complete heavy-duty work.The road grader is equipped with flexible blade suspension system and articulated frame, making it enjoy a wide working range. | |

| 724H | 20000kg | 179kW | 4420mm | Equipped with Cummins engine.Box-typed frame and advanced T/M enable it to complete heavy-duty work.A wide working range is accomplished through flexible blade suspension system and articulated frame. | |

| 726T | 19500Kg | 194Kw | 4422mm | Efficiency and energy savings are achieved through load-sensitive pumps and valves, while the MICO dual circuit hydraulic brake system ensures high security. Optimum axle load allocation provides excellent stability, particularly in rough and rocky areas. With its box-type frame and advanced transmission, it's capable of completing heavy-duty work with ease. The flexible moldboard suspension system and articulated frame offer a wide working range, making it ideal for leveling large-scale ground in mining areas, highways, airports, and more. Specifically designed for mining areas, the 726T Motor Grader offers high strength and sufficient power, perfectly suited for road construction, maintenance, and rock cleaning tasks. | |

| 732T | 28000kg | 246Kw | 4620mm | Equipped with a reliable Cummins QSM11-C330 engine, it ensures reliability and efficiency. Its single-handle electro-hydraulic controlled power-shift transmission with 6 forward and 3 reverse shifts makes operation effortless. | |

| 735T | 28000kg | 268Kw | 4920mm | The 735T Motor Grader is a formidable machine designed for heavy-duty tasks. With an impressive operating weight of 28,000kg and a rated output of 268kW, it offers exceptional power and performance. |

Dingsheng Heavy Industry Machinery Co., LTD. (formerly: Dingsheng Tiangong Construction Machinery Co., LTD.) is 100% owned by China National Machinery Heavy Industry Group Co., LTD., one of the largest construction machinery and equipment manufacturers in China, and is a core member of the world's top 500 enterprises and large state-owned enterprises China National Machinery Industry Group Co., LTD.

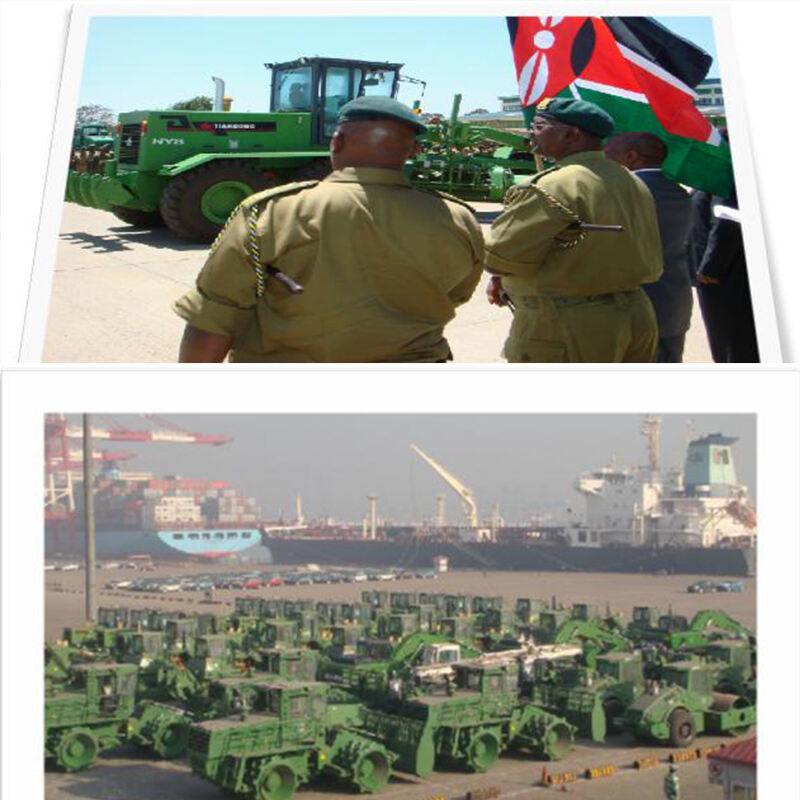

The company cooperates with the world famous enterprises in the construction machinery industry, Hyundai of South Korea and Komatsu of Japan. The products cover a variety of construction machinery products, such as scraper machinery, road maintenance machinery, pavement machinery, concrete machinery, etc., and has the comprehensive ability to provide complete sets of construction machinery for road construction at home and abroad. The products cover the whole country and are exported to more than 80 countries in the world, and the products are installed by the army and participate in the United Nations peacekeeping missions many times.

"Tiangong" brand grader with a complete series, high grade, configuration, unique intellectual property rights advantages, leading the development direction and trend of China's grader, has become the first brand of China's grader, has a high reputation in the country.

| Century-old brand history | |

| 1905 | Tianjin British Concession Agency repair Department |

| 1956 | Tianjin Construction Machinery Factory |

| 1962 | Developed China's first grader P1-90 |

| 1980 | With Komatsu and the Canadian champion grader brand technology cooperation developed PY160A grader, China's only grader factory |

| 1992 | Introduction of the PY180, the industry's first articulated frame |

| 1996 | Tianjin Tiangong Construction Machinery Co., Ltd. occupied 80% of the grader market share |

| 2001 | Listed on Shanghai Stock Exchange |

| 2005 | Dingsheng Tiangong Construction Machinery Co., LTD |

| 2006 | Launched PY180Q hydrostatic, PY80H all-wheel drive grader, Tiangong R & D has been the industry leader |

| 2010 | Dingsheng Heavy Machinery Co., LTD |

| 2013 | Launched DT660, then the world's most powerful grader |

| Since 2013 | Tiangong brand as a core member of the national machinery brand, with the help of the national machinery overseas sales service system, with a full series, high grade, full configuration to overseas |

1. The double row heavy roller chain design in the left and right balance box has an average breaking strength of 26 tons, so as to overcome the problem of easily broken chain during heavy load operation, which is enough to meet the worst working conditions

2. The balance box can swing up and down 13°, making the machine easier to complete heavy duty operations and have good off-road performance; The large steering Angle of the front axle makes the turning radius of the whole machine small, combined with the tire tilt, to ensure the best smooth steering

3. The working hydraulic system uses brand oil pump for oil supply, which is divided to the left and right multi-way valves through the diverter valve, and the local oil path is then realized to combine the flow, and the flow loss is less. At the same time, the use of simple and reliable full hydraulic control, easy to achieve a full range of various actions of the operation, so as to effectively improve the working efficiency of the machine

In 2004, a joint venture company was set up in Malaysia to establish an overseas assembly plant, which is also the first overseas assembly plant in the domestic construction machinery industry, with 3 overseas subsidiaries and 5 overseas offices in the world, and 70 overseas agents and showrooms in more than 50 countries and regions in the world.

The company optimized and developed spare parts procurement channels, the headquarters has a complete spare parts storage center, overseas with a number of spare parts center library, a comprehensive guarantee of spare parts supply, with a variety of means to meet the after-market service needs. For qualified agents, we send overseas service engineers for docking training, and provide a full set of training and design materials issued by the headquarters Marketing Department

1 hour to find the problem, 1 day to solve the problem!

Cis a large group company, the main business for mining, the company has a number of mines, the existing various construction machinery and equipment more than 300 sets. By comparing with the construction of major brands in the industry, the head of client procurement finally chose Tiangong high-horsepower graders, and also signed heavy-duty equipment such as large-tonnage excavators, loaders, and bulldozers. In the course of the customer's operation, one grader found start-up failure. After receiving the feedback of the problem of the equipment, the company quickly responded within 30 minutes, launched the emergency support plan for VIP customers, and multi-directional linkage.

Relevant departments convened relevant personnel to first carry out remote diagnosis services, communicate with customers, remotely access equipment data through the network, quickly identify the cause of the problem and work out detailed solutions with customers. Subsequently, the local market service engineer was dispatched to the fault site for the first time on the same day to quickly diagnose the equipment, and the equipment was restored to normal work in only one hour, which was highly praised by customers. The fast and efficient service of Tiangong made customers marvel!

Tiangong service engineers also provide on-site product guidance to customers, including regular maintenance, inspection and replacement of worn parts to prevent equipment failure. Establish feedback channels with operators and encourage them to provide comments and suggestions during the use process, so that the company's products can continuously improve products and services.

At the same time, Tiangong's "2024 service Journey" brand service tour activities will be carried out regularly with joint agents, and it is planned to build a regional spare parts storage center to provide customers with the best quality service with the most professional technology, the fastest response and the most enthusiastic.

In March 2023, the online website of Tiangong Brand received an inquiry from an African country, and the purchase intention was centered on the bold vision of revitalizing the country's rural roads proposed by a new president of an African country when he took office. One of the key measures of the new government is to purchase quality equipment such as graders and road rollers in bulk to facilitate the repair and maintenance of rural roads. The move is aimed at addressing chronic infrastructure deficiencies in rural areas.

In addition to the procurement of road maintenance equipment, the Government is also focusing on capacity-building and skills development in local communities. This approach aims to involve residents actively in the maintenance and rehabilitation of rural roads and ensure the long-term sustainability of infrastructure improvements.

After mastering the actual needs of the local terminal market, Tiangong promoted the online customer to visit the offline, Tiangong digital Marketing Department sent staff to Africa to conduct online customer on-site service and maintenance training, solved the practical problems of customers, won the trust of customers, developed customers into agents and dealers, and further cooperated with customers to participate in local exhibitions. He developed an emotional bond with the dealer and landed a $1.2 million deal in May.

Government of Uganda Projects

Government of Uganda Projects

Government project of Togo

Domestic military project

Tiangong factory area: 175512 square meters

Number of employees: 1110

We provide contract manufacturing business for Wackerneuson, TEREX, JCB, KATO, Hyundai, Atlas, SANY, Milacron and other international well-known brands.

With more than 60 sets of imported lasers, flame cutting machines, imported manipulator bevelling machines, large CNC bending machines and imported welding robots, it can achieve a deep processing capacity of 100,000 tons/year of steel, and also has more than 120 sets of various imported processing centers. It is the first in the industry to be equipped with a shot blasting coating automatic line and imported multi-purpose furnace production line. Quality inspection is equipped with large-scale three-dimensional testing equipment to ensure that every high-quality product exported has ISO SGS TUV CE EPA EAC certification.

Communication and docking

Product matching

Technical scheme reference

Sign cooperation

Mechanical production/deployment

Quality inspection

Despatch

After-sales service