No.898 West Huanghe Road, Changzhou, Jiangsu, P.R.of China +86-182 06118609 [email protected]

Equipped with Cummins (weichai)engine, strong power, high efficiency, energy saving, reliable and durable; advanced negative flow hydraulic system, comfortable operation, high operating efficiency, excellent cost performance; full power control, four power modes to adapt to different working conditions; stepper motor accurately controls the throttle , Significantly reduce fuel consumption; full 3D modeling and finite element analysis technology to ensure the reliability and stability of structural parts.

1.The original imported turbocharged engine has strong power, low fuel consumption, strong adaptability to high altitude, or the optional Weichai engine has strong power, sufficient power, and a fuel consumption reduction of more than 5%

Adopting internationally renowned hydraulic components with excellent performance and high reliability.

The new load sensitive hydraulic system is equipped with a cross stage large displacement constant power variable pump matched with a new generation of low-pressure loss main valve. The entire machine has fast response speed, high efficiency, low energy consumption, and smooth and accurate operation.

2.The upper frame adopts modal analysis technology, which is sturdy and durable while effectively reducing machine vibration and noise.

Comprehensive optimization of structural component design, strengthened treatment of key stress positions, fearless of adverse working conditions.

The bottom plate, side plate, and reinforcing plate of the bucket are all made of high-strength wear-resistant materials to improve the durability of the bucket.

3.Fully injection molded interior, with effective color matching based on ergonomics, not easily causing visual fatigue for operators.

The driver's cab with high-strength irregular pipe frame structure, equipped with fire extinguishers, escape hammers, safety belts and other equipment, has a wide front and rear view, and high work safety.

High power air conditioning, three-dimensional air outlet; Suspended seats with secondary slide adjustment; Excellent shock absorption and noise reduction performance can achieve perfect and comfortable driving and riding.

4.40 years of R&D and manufacturing experience in the four wheel area, with high-end technology in the industry, the preferred choice for excavators.

Mature and high-quality forging heat treatment process, stable and reliable quality.

Equipped with supporting wheels of the same specification as the 7T level, sturdy and durable, with a long service.

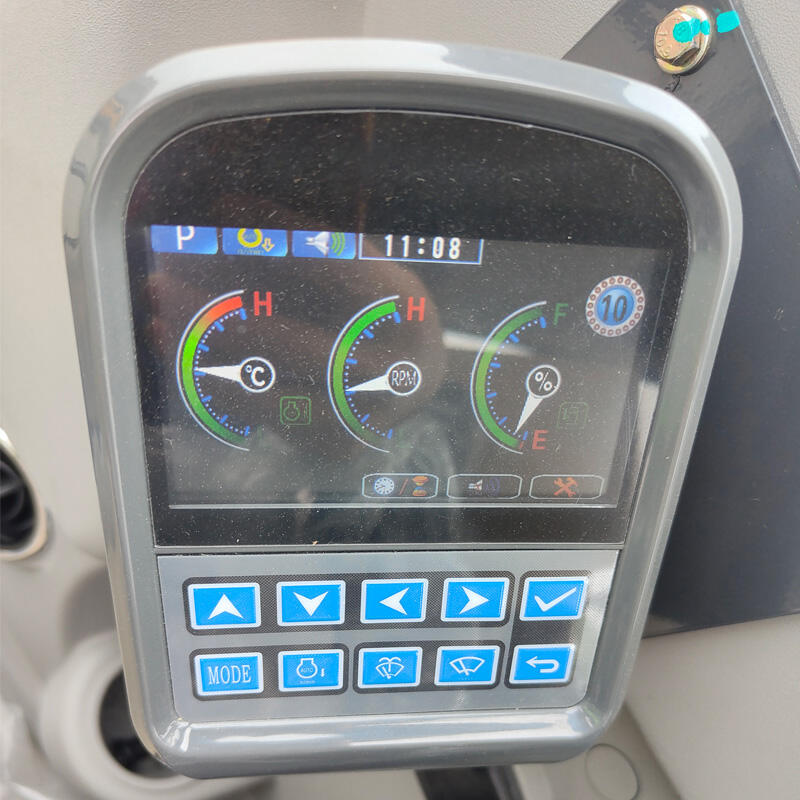

5.The intelligent control system achieves a high degree of matching between the power system and hydraulic system, improving work efficiency and reducing fuel consumption.

The new generation of human-machine friendly intelligent electronic control system allows you to fully grasp the working status of your machine.

There are four preset working modes: P (heavy load mode), E (economic mode), A (automatic mode), and B (crushing hammer mode), which are convenient to switch between.

Through the cloud platform, relevant information such as the location, running trajectory, and working status of vehicles can be viewed at any time.

6.The washer is located on the left side of the engine compartment for easy inspection and filling

Fully open engine hood with positioning mechanism, easy and safe to open, large engine compartment space, convenient for maintenance and repair.

The electrical components are centrally arranged in the right front toolbox compartment for easy inspection and maintenance.

Cooling fluid filling and air filter replacement are within reach.

| Overall length | 5855 |

| Ground contact length (Transportation) | 3330 |

| Overall height (to top of boom) | 2060 |

| Overall width | 1880 |

| Overall height (to top of cab) | 2610 |

| Counter weight ground clearance | 710 |

| Ground clearance | 360 |

| Tail swing radius | 1655 |

| Tread | 1990 |

| Track length | 2560 |

| Track gauge | 1480 |

| Track width | 1880 |

| Shoe width | 400 |

| Bonnet height | 1780 |

| Revolving frame width | 1655 |

| Distance from swivel center to tail | |

| Max. digging height | 5785 |

| Max. dumping height | 4075 |

| Max. digging depth | 3850 |

| Max. vertical digging depth | 3000 |

| Max. digging distance | 6200 |

| Max. digging radius at ground level | 6060 |

| Min. swing radius of work equipmen | 2395 |

| Max lifting height of bulldozer | 385 |

| Max cutting depth of the bulldozer | 465 |

| Hydraulic pump form | REXROTH |

| (L/min) | 152 |

| (m3)Ratedbucketcapacity | 0.11~0.22(0.22) |

| (mm)Bucket width | 810 |

| (r/min)Swingspeed | 12 |

| Brake type | Pressure release, mechanical braking |

| (kN)Stick digging force | 29 |

| (kN)Bucket digging force | 48 |

| (kg)Operatingweight | 5960 |

| (kpa)Groundpressure | 33 |

| traveling motor | Axial variable piston motor |

| (km/h)Travellingspeed | 4.6/2.7 & 4/2.6 |

| Max.traction | 50 |

| Gradeability | 70%/35° |

| (L)Fueltankcapacity | 105 |

| (L)Cooling system | 10.4 |

| (L)Engine oil quantity | 10 |

| (L)Hydraulicsystem | 74/110 |

Our friendly team would love to hear from you!