No.898 West Huanghe Road, Changzhou, Jiangsu, P.R.of China +86-182 06118609 [email protected]

Operating weight:19500kg

Rated output:175kW

Rated load:6000kg

The ZL60H Wheel Loader epitomizes cutting-edge engineering and ergonomic design, boasting a hefty operating weight of 19,500kg, a powerful rated output of 175kW, and a substantial rated load capacity of 6,000kg.

Its main frame features an innovative 'paired' tapered roller bearing structure enhancing articulation reliability, especially in challenging conditions. The machine includes a ZF4BP210 double-variable system with an electro-hydraulic power-shift gearbox for effortless and safe operations, ensuring high efficiency. Steering is revolutionized with a small-displacement gear and a low-pressure load-sensing system, making maneuverability exceptionally light and reducing operator fatigue. Additionally, its hydraulic system is designed for optimal heat dissipation, ensuring reliable performance under all conditions. The 966 model sports a T series appearance with easily accessible large doors for simple maintenance, while the cab is re-engineered for maximum sealing and minimal noise, significantly surpassing national standards. Centralized control for relays, fuses, and maintenance points underscores its user-friendly design, streamlining maintenance and enhancing convenience.

| Overall Dimension | ||

| 1 | Length(with bucket on ground)* | 8714(mm) |

| 2 | Width(to outside of wheels) | 2965(mm) |

| 3 | Bucket width* | 3048(mm) |

| 4 | Height(To the top of the cab)* | 3550(mm) |

| 5 | Wheel base | 3300(mm) |

| 6 | Min. ground clearance | 498(mm)? |

| Technical Specification | ||

| 1 | Rated load | 6000(Kg) |

| 2 | Operating weight | 19500KG |

| 3 | Rated bucket capacity | 3.7(m3),可选2.6-5.0 (m3) |

| 4 | Max. dump clearance | 3393(mm) |

| 5 | Dump reach | 1365(mm) |

| 6 | Min. turning radius(wheel) | 6350(mm) |

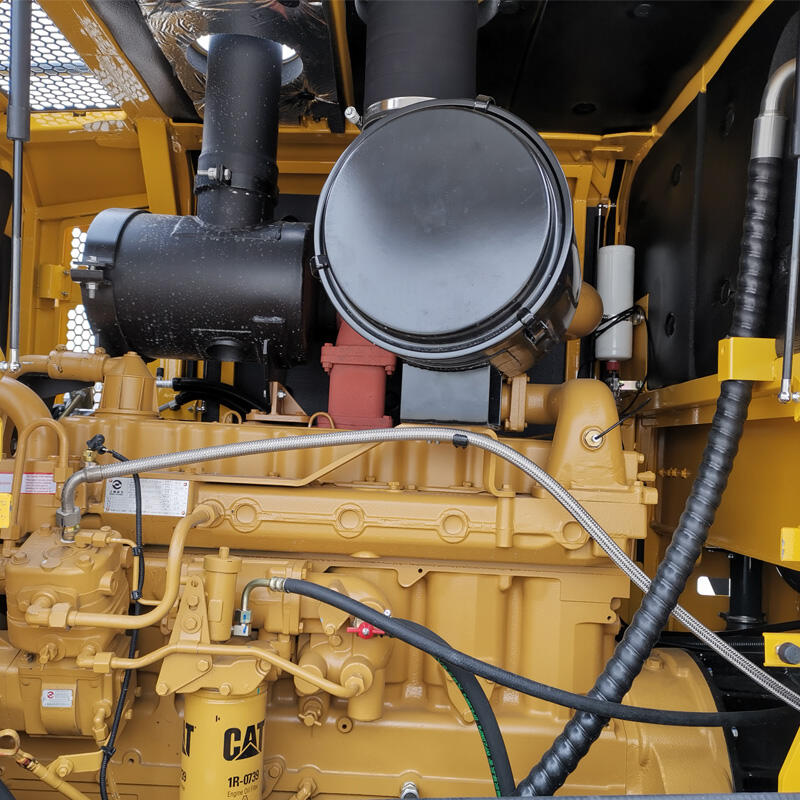

| Diesel engine | ||

| 1 | Model | ShangChai SC11CB240.1G2B1 |

| 2 | Type | Direct injection. |

| 3 | Rated output | 175 (kW) |

| 5 | Total exhaust of cylinder | 10.5(L) |

| 9 | Rated speed | 2200(r/min) |

| 10 | Max. Torque | 912(N.M)@1400 r/min |

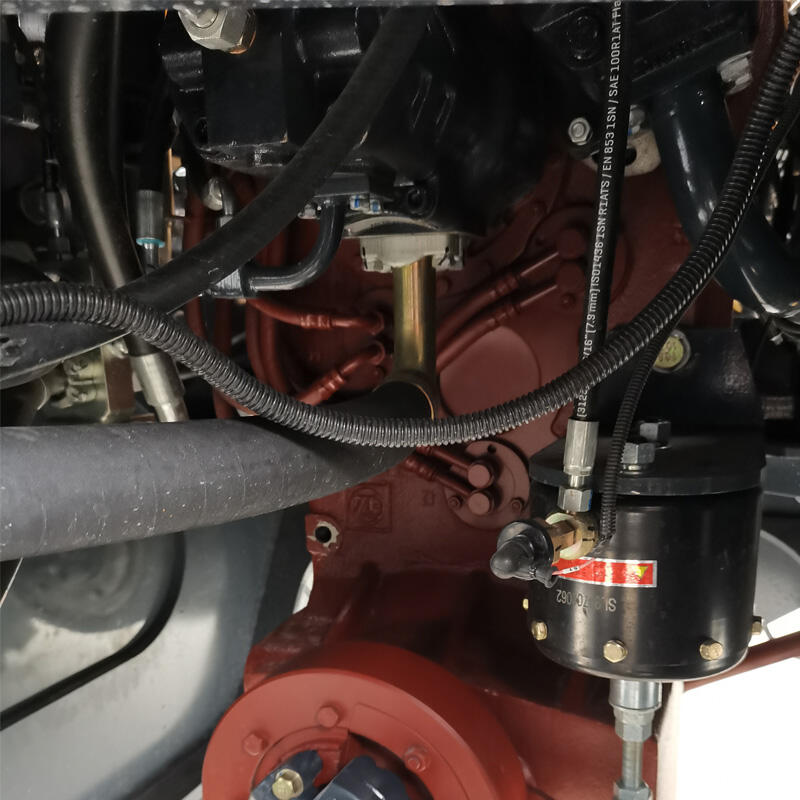

| Transmission System | ||

| 1 | Model | ZF采孚 4BP210 |

| 2 | Type | 3-elements single stage |

| 3 | Gear shift position | 4F, 3 R |

| 4 | Speed(F/R) | Forward:6.78/13.24/24.38/37.45km/hReverse:7.15/13.93/25.48km/h |

| 5 | Max. drawing force | 180kN |

| 6 | Size of tire | 23.5-25-20PR |

| Working Hydraulic System | ||

| 1 | Model of oil pump | SGP2100-2080-02020R01 |

| 2 | System pressure | 20MPa |

| 3 | Model of Muti-way directional valve | D32Ⅱ-YL20 |

| 5 | Pilot valve | DXS-00 |

| Steering System | ||

| 1 | Model of steering pump | SGP2100-2080-02020R01 |

| 2 | Model of redirector | BZZ3-E100B |

| 3 | Model of flow magnifying valve | ZLF25A11 |

| 4 | System pressure | 16MPa |

| Brake System | ||

| 1 | Type of traveling brake | Caliper disc brake |

| 2 | Air pressure | 6-7.5(kgf/cm2) |

| 3 | Type of parking brake | Manual control cutting-off air brake |

| Oil Capacity | ||

| 1 | Fuel(diesel) | 350(L) |

| 2 | Engine lubricating oil | 24(L) |

| 3 | Oil for converter and gear box | 35(L) |

| 4 | Oil for hydraulic system | 245(L) |

| 5 | Oil for driving axles(F/R) | 30/24(L) |

The main frame articulation is innovatively designed with "paired" tapered roller bearing structure, which increases the contact area and ensures the reliability of articulation even under bad working conditions.

ZF4BP210 double-variable system is adopted, and the gearbox is electro-hydraulic operated power-shift fixed-axis type, and it can realize forced downspeed, which is easy and safe to operate and has high operating efficiency.

the use of small-displacement steering gear and low-pressure control of the load-sensing hydraulic flow amplification valve steering system, so that the steering wheel is very easy to maneuver flexible, greatly reducing the labor intensity; steering wheel adjustable device, so that the operation of the more comfortable and convenient.

Based on simulation and test verification, the innovative design of shunt heat dissipation hydraulic system enables the hydraulic system of the whole machine to get reasonable and sufficient heat dissipation under any working conditions, and improves the efficiency of radiator use and the reliability of the hydraulic system.

T series appearance shroud large door design, radiator front air inlet and rear air outlet can be opened. The new cab is upgraded with super sealing, and the noise of the whole machine is far lower than the national standard.

The relay and fuse box of the whole vehicle are centrally arranged, the grease nipple of the working device is led to the side of the frame, and the pressure measuring port is arranged in the front of the auxiliary box, etc. The humanized design makes maintenance more convenient.

Our friendly team would love to hear from you!